Begin Energy Saver/Doubler Commission

November 19, 1982 marked the beginning of efforts to cool down and operate the E and F Sectors of the new Saver superconducting accelerator. This test is the beginning of the Saver commissioning.

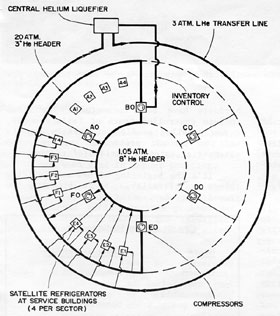

Last winter and spring one-eighth of the Saver ring was tested. Included in the test were 2 compressor buildings (A0 and B0), 3 refrigerators (Al, A2, and A3), 2 miles of transfer line, and 2700 feet of superconducting magnets. By comparison, the E and F Sector test is a one-third ring test consisting of 3 compressor buildings, 8 refrigerators, the complete 4-mile transfer line, and 7200 feet of the accelerator. The two sectors include 258 dipoles, 80 quadrupoles, and about 100 other tunnel components.

The goals of this test are well defined. Successful operation of the controls system, refrigerator and compressor reliability, power supply performance, and the quench protection monitoring system communication are complex tasks that have added to the excitement around the Main Control Room during the last few weeks.

This test is crucial for the controls system. With the knowledge obtained from the A-Sector test several improvements in the algorithms to control the refrigerators and compressors have been made and will now be fully tested. One goal is to have a fully automatic system by the end of the test. The task is far from easy; with two sectors working and three compressor buildings and the Central Helium Liquefier in operation, 53 feedback control loops must work in harmony. This number will steadily increase as the rest of the ring becomes operational. Upon completion of the Saver commissioning, there will be 353 control loops in operation.

A second goal for the controls system is to have a "system" approach to the controls of the compressors to avoid possible oscillations in the transfer line. The compressor controls will be centralized using the VAX system instead of only using distributed intelligence residing in the microprocessors that control each of the compressor houses.

The power supply and quench protection tests in E and F Sectors will take on a considerably different flavor than they had during the A-Sector test earlier this year. The A-Sector test included attempts to stress the components to their worst-case conditions. This winter, the approach is one of kid gloves, not a sledge hammer. Any spectacular, large-scale quenches will be unscheduled.

The system has grown considerably in complexity in moving to one-third ring testing. There are four 1 kV power supplies in use, and 8 quench protection monitors communicating through a new link that is in place around the ring. There was much activity both in the service buildings readying the hardware and in the software development. The magnets are full of liquid helium and have successfully been hipotted, and the cables between the superconducting bus and the quench protection hardware have been connected. The plans include controlled tests of failure modes, a few detailed studies of certain aspects of the quench protection system, and attempts at extended periods of ramping.

It's the beginning of new and exciting things for Fermilab. We're breaking new ground every day.

Schematic draining of the liquid and gaseous helium system for the Energy Saver.

Manuel Martin at the Saver control console recalculating parameters for loop controls for compressors