Booster Installs Last of 96 Magnets

It was a busy, fruitful December for NAL’s Booster Section. Approximately four months ahead of its original and formal schedule, the Booster group completed the precise installation of the 48 complex girders carrying 96 magnets in the 500-foot diameter Booster tunnel at the Main Site.

The heavy installation work was completed at noon on Monday, December 14; a week later, on December 21, the Booster Ring was completely aligned and a vacuum was achieved all around. The first "topping off" was observed with an informal party in the tunnel; the second was celebrated with a party at a restaurant near the NAL site.

In the impressive and intricate triad of the NAL accelerator system, the Booster, so to speak, is the "sensitive middle-man" -- the vital link between the Linear Accelerator and the Main Accelerator. The NAL Booster is designed to accelerate protons to Eight Billion Electron Volts (BeV) at the rate of 15 pulses per second.

The Booster, which will receive the proton beam from the Linac at an energy of 200 Million Electron Volts (MeV), is one of the few "rapidcycling" booster synchrotrons in the world. In the esoteric field of elementary particle physics, two other "booster" accelerators are being built at this time -- one at CERN in Switzerland for its 28 BeV accelerator and another for the Zero Gradient Synchrotron at the Argonne National Laboratory.

The NAL Booster synchrotron, unlike the Main Accelerator’s separated function system, is a combined-function design, but in many other respects it is similar to the Main Accelerator. It is housed in a similar semi-underground enclosure, with equipment galleries above. Earth shielding will keep radiation levels in the galleries below permissible tolerance levels.

Each of the 48 steel girders in NAL’s Booster Ring has two magnets, which are made of laminated silicon steel sheets 1/40th of an inch thick. Each girder is 23 feet long and four feet in height, includes three capacitor banks, a titanium-ion vacuum pump and a transformer. Full power tests are being carried out on the Ring, including power supply operation through the control system.

Roy Billinge, Booster Section Leader, is pleased by the accomplishments of his staff. He lauds the team work of his group and the support of many sub-contractors. For example, when a major problem developed with one of the magnet suppliers, Will Hanson was able to increase magnet fabrication in the Booster Lab Building reaching a peak production rate of two magnets per week. The fabrication crew, under the leadership of Leo Ray and including Del Miller and Bob Jensen, built more than twice as many magnets as orginally planned so that about one-third of the installed magnets were built here at NAL.

Prior to installation in the enclosure the Booster "modules" undergo pre-assembly at the Main Ring’s West Chicago facility under the supervision of John Clark. In parallel with this, magnets are measured carefully by optical means by Jon Sauer and Bobby McNeal. They are then optically set on the girder and all power and water connections made, under the supervision of Jim Humbert. Next, the module is powered, in series with a "standard" module, and by means of current carrying wires stretched through the magnet gaps. At this point, Bob Peters and Harland Gerzevske compare the magnetic fields of the production magnets with the standard prototypes. The vacuum chamber is then welded in place, between the magnets, the vacuum pump installed, and the whole assembly leak-checked.

Following installation in the Ring, the modules are surveyed into position by Jim Walton, Tom Topolski and Billy Shumate. Finally, the module is connected to the power/cooling supply and integrated into the Ring vacuum system by Umer Patel and his team of technicians.

"During January," says Billinge, "we hope to begin attempts to circulate a proton beam around the Booster. And, we are expecting to get acceleration during February. Once we have achieved acceleration, somewhere about one BeV, we expect to extract the beam and transport it to the Main Ring.

"There are more persons who should be thanked for their work than I can name here," says Billinge. Re especially noted the untiring efforts of his Associate Section Leader, Helen Edwards. Among others were Ed Hubbard, Roland Juhala and Bill Martin, for their efforts on the 200 MeV beam-transport system; Lowell Klaisner and John Dinkel for their work on the controls and beam detectors. "I simply cannot say enough good things about all of the Booster people. I just think they have done a great job," says Billinge.

Among contractors Billinge cited employees of Belding Engineering Company of West Chicago, who had worked with efficiency and diligence to transport and place the Booster girders properly in the tunnel. 1971 will continue to be a busy year for the Booster group. On his calendar, Billinge has several more major milestones to be achieved. Most important is to record a Booster accelerator energy of Eight Bev by about May 1.

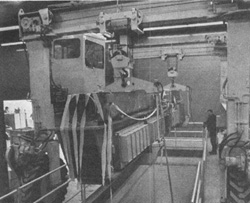

Cross Gallery "travel-lift" machine lowers 48th girder, supporting final two Booster magnets Photo by Tony Frelo, NAL

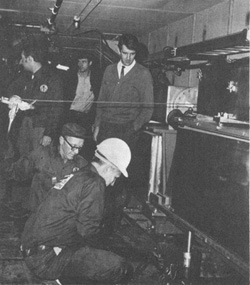

Belding Engineering Co. employees use rope pulley instrument called a "come-along" to install the 48th girder supporting final pair of Booster Ring magnets. Roy Billinge, Booster Section Chief, stands at far right watching the event. Behind Billinge is Bob Peters, NAL physicist. Photo by Tony Frelo, NAL