Main Ring's Final Pre-Cast Section Lowered into Place

On January 2, 1970, DUSAF, the architect-engineer and construction management firm for the National Accelerator Laboratory, awarded a contract to the Corbetta Construction Company of Illinois, which has its headquarters in suburban DesPlaines. The contract was to construct the final five-sixths of the NAL Main Accelerator Enclosure.

Design, fabrication and testing of the preaccelerator to the present time has been primarily the responsibility of Cyril Curtis, physicist; Glenn Lee, mechanical engineer; and Charles Sharp, Gregory Urban, Raymond Hren and James Wendt, technicians. Many other persons in the Linac Section and elsewhere have made important contributions in bringing the system to its present stage of completion. A part of the construction was accomplished in the Physical Science Laboratory of the University of Wisconsin. The assistance of Argonne National Laboratory in the loan of their high voltage supply, while the NAL supply is under construction, made the early testing of the preaccelerator possible.

NAL's main synchrotron will be housed in this ring-shaped enclosure approximately 20,600 feet in total length. The tunnel, which, incidentally, is located in both DuPage and Kane counties, is four miles in circumference and 1.24 miles in diameter. The "Main Ring," as it is called, will house 774 bending magnets and about 240 focusing magnets.

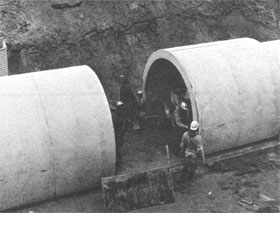

At approximately 4:00 p.m., Monday afternoon, November 30, the final pre-cast concrete section was placed in the Main Accelerator Enclosure. A beer and pizza party with Charles Marofske, NAL Personnel Manager, as maitre'd, followed for Corbetta, DUSAF and NAL staff members. A repeat of the "final closing" was held for the news media at 1:00 p.m. Tuesday, afternoon, December l.

It took ten minutes to mix the cement used to bind the pre-cast concrete section to the slab. Then the concrete was transported by hoist to workmen waiting in the tunnel area. In another 10 minutes, the effort was completed. Then Robert R. Wilson, NAL's Director, and E. Parke Rohrer, DUSAF Project Manager, scrambled down the muddy excavation to shake hands with cement finishers and laborers who had worked so hard to complete the enclosure several weeks before schedule.

"I was pleased especially by the efficiency and competence of the Corbetta workmen in their performance on the Main Ring Enclosure," said Parke Rohrer. He added that NAL had been fortunate, by and large, to have found a series of experienced professional sub-contractors to work on general construction of the Laboratory. He also thanked Corbetta and other sub-contractors for their cooperation in the NAL and DUSAF equal employment opportunity and affirmative action programs.

Corbetta was given its formal notice to proceed with construction on its $7,300,000 contract nearly 11 months ago. The first one-sixth of the Main Ring Enclosure had been constructed by the Schless-Madden Joint Venture, of Batavia, also hailed by Rohrer for their competence. Hundreds of workmen with varying skills have worked on the accelerator enclosure.

The Main Ring Enclosure consists of 1,790 pre-cast concrete sections. Each section is nine feet high, 10 feet wide, 10 feet long and 10 inches thick. The sections are placed on a poured concrete slab approximately 20 feet below ground. Special vehicles are planned for moving equipment and personnel.

In the completed tunnel, accelerator magnets are located close to the outside wall, leaving an 86-inch clear space for vehicles and personnel. Above ground, utilities for the main accelerator will be distributed through 24 service buildings spaced uniformly along the inside perimeter of the ring. Each building will be about 2,000 square feet in area. Most already have been completed. They will contain magnet power supplies, cooling-water pumps, heat exchangers, vacuum-pump power supplies, ventilation equipment and circuitry for control multiplexing and transmission. Six utility buildings will contain additional equipment related to the cooling towers to be located nearby. The four-mile enclosure, along with associated service and access buildings, contains some 36,000 cubic yards of concrete. About 2,750 tons of reinforcing steel also were used in the enclosure. Tunnel excavation alone involved transporting about 960,000 cubic yards of earth. Earth shielding is being used to cover the entire enclosure and the entire tunnel will be covered in the next few weeks.